- Details

- Piping General Arrangement Drawings (Piping G.A.’s)

- Piping Isometrics 3. Piping Material List

- Piping ISO-System Drawings

- Rules for Executing Piping Design Work for Revamp Projects

- Instructions for Checking Piping Documents

Attachments

- Production Flowchart of Pipng Documents

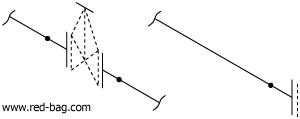

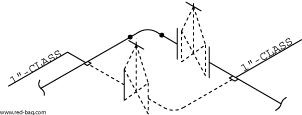

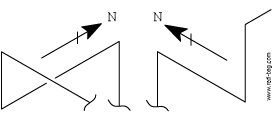

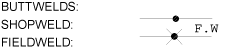

- Drawing Symbols

- Nozzle Data

- Line Attachments

- General Abreviations

- Piping G.A. Revision List

- Free Handsketch for APD-ISO

- System Drawings Example

- Piping Material List

NOTE:

This guide lays down the standard requirements of Red-Bag.

Client’s requirements shall take priority over Red-Bag's

standard methods, when specifically directed.

1. Piping General Arrangement Drawings (Piping G.A.’s)

Preparatory Work to Produce PIPING G.A.’s

Prior to being able to produce any adequate PIPING G.A. in an efficient manner, it is essential that sufficient piping studies are prepared with the aid of agreed/approved plotplans, PEF’S, PEUF’S and Piping Data Sheets (line designation tables).

These piping studies shall then be used as “coordination studies” to inform/collect comments from other disciplines such as process engineering department, projectengineering department and all relevant design engineering departments.

If on a project a detail design model is provided, these coordination studies shall also beused to execute further design work on the model.

The interrelation of PIPING G.A. preparation with the plotplan, the piping studies, the model(if any) and the piping handsketches is shown on the production flowchart for piping designdocuments. See Attachment A.

Drawing symbols shall be in accordance with Attachment B.

Nozzle data shall be in accordance with Attachment C.

Line attachments shall be in accordance with Attachment D.

General abbreviations shall be in accordance with Attachment E.

Revisions to piping g.a.’s shall be indicated on piping g.a. revision lists per drawing issue.See Attachment F. Revisions to PIPING G.A.’S shall at all times refer to line numbers.PIPING G.A.’S shall under no circumstances be re-issued for any change which is notrelated to piping. Such a change in itself may be a necessity. It is not a reason for re-issueof the drawing unless/until it affects the piping layout.

Note: the use of clouds on PIPING G.A.’S to indicate revisions is prohibited.

Procedure for Presentation and Numbering of Documents andDrawings.

Drawing instructions

Size of sheet

A. A1 format (594 x 841) sheets shall be used.

B. The use of other than A1 format shall be discussed with the squad leader.

Scale

A. 1 : 33 1/3 shall normally be used for piping within an area, also for unit pipe racks.

B. 1 : 75 shall be used for yard rack piping plan views.

1 : 33 1/3 scale may be used for sections through rack.

C. Where there seems to be a reason for any other scale, the matter should be

discussed with the piping squad leader.

D. Dimensions shall be given in mm. No dimension less that 1 mm shall be used.Printing of notes etc. Shall not be less than 3,5 mm high. To obtain a readablelettering for microfilming.

E. A figured scale stick of 100 mm long shall be preprinted on the vellum in the marginof the drawing to indicate original scale.

Workspace

A plan shall be placed on the drawing sheet the same way it appears on the plotplan (i.e.same north arrow as plotplan). The north arrow shall be placed on all plans in the upperright hand corner of the sheet, using the standard north arrow sticker. See attachment b,sheet 1.

Fixed Items

Fixed items such as match lines, steelwork, platforms, cable trays, equipment outlines shallbe drawn on the reverse side of the vellum (equipment nozzles shall be considered as partof piping). The squad leader or his designate shall check completeness and accuracy ofscale of all basic piping g.a.’s prior to designers/draftpersons drafting the piping on the frontside of the vellum.

The scope of the drawing is determined from the “key-plan” of piping drawings. Confirm the cut off elevation and drawing title from the drawing index, prepared by the squad leader.

General Notes

General notes, reference drawings and tables shall be included in the area above the title and the issue block.

The following notes will appear on the “a” or grade drawing for each piping area.

A. Company high point of grade elevation = 100.000 mm is equal to (Client’s Name)

elevation _ _ _ _ _ _ _ _ _ _ mm.

B. For general notes and reference drawings see area identification plan BN- .... -00102.

The Nozzle Table

The nozzle table is placed at the top right hand corner of the drawing sheet. A completed example is to be found in Attachment C. Maximum use must be made of abbreviations,reference Attachment E.

Plan Views

Dimension lines defining the location of columns, steelwork and equipment shall be placed, if possible, outside the match lines. Dimension lines for piping can be placed, if more convenient or clear, inside the match lines.“Closing” dimensions will be given, the rule is “do not over dimension”. If part of a layout can be clearly shown with two dimensions, do not give four. However, to suit apd requirements,“string” dimensions for piping is mandatory. All elevations of pipe will be center line of pipe.

All dimensions and notes on a drawing shall be read from the bottom or right hand side ofthe vellum.

Design Information

Designers, draft persons, and checkers shall incorporate the latest information on a drawing by constantly checking the following document masters:

Flow Diagrams and Line Tables (Data Sheet Piping)

Plotplans and Key-Plans

Coordination Studies (Initial Plot Studies)

Stress Comments and Sketches

Equipment Drawings

Structure and Platform Drawings

Foundation and Underground Drawings

Piping Specifications

Engineering Design Guides (e.g. C1 - Issued for Job)

Job and General Standards

Pipe Sketches for Calculations by Process Department.

Should it be necessary to depart from the arrangement shown on the flow diagram orcoordination studies, the

squad leader shall be informed. If the change is agreed proceedas follows:

Flow Diagrams

The change shall be agreed with the Project Engineer, and be recorded on the master flowdiagram.

Coordination Studies

The piping squad leader shall agree to the change, and inform other sections.

Design Features

Outline all structural framing including platforms, etc. Also locate and identify structuralcolumn lines in accordance with the plot plan. Show the elevations of all platforms. Drawunderground drain tundishes, electrical- and instruments cable trays and trenches. Indicateall local electrical- and instrument cabinets and junction boxes.

For method of identifying structural columns, see Attachment B, sheet 1.

<Part removed from the public section of the website>

Methods of Presentation

To distinguish between material needed for the actual pipe fabrication in the pipe shop and erection of field material, the shop fabrication items are represented by a full (not heavy) line ______________ , and erection components like valves, blind flanges etc. are drawn dotted --------------.

Continuation runs on terminal points or branches should only be extended to a minimum and are shown by a full thin line. Descriptions and identifications of these points are given on page 10.

Continuation runs of field fabricated pipe will be shown dotted if to be included on the isometric.

Pipe details shall have the same north orientation to the furthest possible extent.

Branch Connections

<For full version, purchase access to the registered section of the library>

- Details

The Library section of the Red-Bag website contains information for the process industry from the perspective of the Owner Operators and the Engineering Contractors of process plants. The content of this section will be update and expanded regularly with new information.

The software tutorials section contains information, links and getting started guides about the Red-Bag software. The software applications are calculation tools for vessels, exchangers and pipe components.

The papers section provides information about technical subjects and the Red-Bag philosophy related to the subject. For example: technical data on documents and drawings are exchanged between vendors and customers. Many information is checked and duplicated (sometimes by hand) which is time consuming. A paper discusses this subject and highlights which information should be transferred.

Quality Documents, Work Instructions, Guides, Standards, Specifications, Forms

The remaining sections are parts of a full Quality Assurance system, starting with general QA documents to very detailed design standards and forms. The documents are for reference only. We would appreciate that if content is copied or used in other documents, that the Red-Bag site is indicated as your source of information.

The objective of a QA system is to provide a documented system for the structured activities within the company which promote efficient and cost effective operations resulting in quality products/services that satisfy client requirements.

The further objective is to provide an internal working document for the company work procedures. To promote uniformity of working methods throughout, the appropriate procedures should be implemented at all times without deviation.

- QA standards - This Quality Assurance Manual contains the subjects, tasks, measures and general responsibilities of Company's department and project activities compiled as a company Assurance Program

- General procedures - The Company Procedures Manual is a collection of Company's interdepartmental and administrative procedures.

- Detail procedures - This level of procedures covers the activities within and limited to individual departments or discipline.

- Work instructions - Work instructions give details how activities, that are referred to in procedures, shall be performed.

In addition to the mandatory company documentation system, departments and disciplines may establish documents for easy reference. Information for the implementation of operations can be taken from:

- general guides

- engineering and design guides

- general standards

- engineering and design standards

- standard specifications

- standard requisitions

- standard forms

The accounting and estimating procedures use cost- or commodity codes to identify activities and hardware. The cost codes cover all material and activities use during the execution. The forms are standard documents that are used during project execution. Examples are construction forms for inspection and forms for reproduction of documents.

- Cost Codes

- Forms

Refer to the Credits page of this website for the source of these QA documents

Quality Assurance Standards

The Quality System documents are usually related to the QA standard implemented such as the ISO 9000. The documents in this section have been written from the perspective of an Engineering Contractor. Their focus is on project execution rather than operating a process plant or performing maintenance on equipment. However the general procedures can be used with some modification in most organizations.

General Procedures

The general procedures are divided in general and operational procedure. The general procedures contain corporate standards, management and administrative procedures. The operational procedures are primarily related to project execution because the procedures are written from the perspective of an Engineering Contractor.

Work Instructions

The work instructions are the lowest level documents that can be part of a QA system. They provide detail instruction how to perform the applicable tasks as indication in the ISO 9000 standard. The focus of the work instructions is primarily related to project execution because the procedures are written from the perspective of an Engineering Contractor.

General Guides

The general guides are related to executing work such as inspections, auditing but also guide lines for testing for example equipment. These guides are usually not part of the auditable section of the QA system. The focus of the guides is primarily related to project execution because the procedures are written from the perspective of an Engineering Contractor.

Design Guides

The design guides section contains examples and descriptions for the exection of engineering work. Part of this section is for example a plant layout guide. The extensive guides, such as the Plant Layout guide, are split in a number of pages, refer for example to BN-DG-C1X serie.

The guides are mainly related to the detail design disciplines, such as mechanical, piping, instrumentation, civil and project engineering.

Engineering Guides

The engineering guides are intended for executing work such as engineering calculations, prepare reports or preparing engineering documents. These guides are usually not part of the auditable section of the QA system. The focus of the guides is primarily related to project execution because the procedures are written from the perspective of an Engineering Contractor.

General Standards

The general standards provide examples, templates and basic information for preparing general project execution documents These standards are usually not part of the auditable section of the QA system. The focus of the guides is primarily related to project execution because the procedures are written from the perspective of an Engineering Contractor.

Design Standards

The design standards provide ready to use examples and design dimensions for equipment, piping and other disciplines. These standards are usually not part of the auditable section of the QA system. The focus of the guides is primarily related to project execution because the procedures are written from the perspective of an Engineering Contractor.

Engineering Standards

The engineering standards contain ready to use examples and tools to perform engineering work. The standards part is limited but will be further updated with tools made by Red-Bag.

Specifications

Specifications are documents that describe the general requirements for a type of service or the type of equipment. The (general) specification provides the overall basis for a minimum quality and safety of the scope of work. The details for a service or equipment is part of the requisition.

Requisitions

The requisition provides the detail requirements for an equipment or a service. The general requirements are listed in the general specification supporting the requisition. The (general) specification provides the overall basis for a minimum quality and safety of the scope of work. The details for a service or equipment is part of the requisition.

Forms

The forms are ready to use templates for communication and reporting type of documents. The nature of the document ranges from general administration, project execution to construction reporting.

Cost Codes

The Project Account and Cost Code system presented in the sub (web) pages are organized in main categories. The categories are also refered to as 'Accounts'.