This is a LIVE STUDY document and will be changed without notice. The content may contain errors and omissions.

|

ASME B31.1 (2008) |

ASME B31.3 (2008) |

ASME B31.8 (2007) |

|---|---|---|

|

Power piping: typically found in electric power generating stations, in heating and cooling systems |

Process piping: typically found in petroleum refineries, chemical, pharmaceutical, textile and paper plants |

Gas transportation and distribution systems: piping transporting products, predominantly gas |

|

Applicable: boiler external piping from first joint up to and including first block valve for boilers where:

Excluding: fatigue due to pressure cycling

|

Exclusions:

Including: fatigue due pressure cycling and thermal cycling

|

Exclusions:

|

|

Allowable stress:

|

Allowable stress:

|

Allowable stress:

|

|

Materials: material of unknown specification shall not be used for pressure containing components |

Materials: material of unknown specification shall not be used for pressure containing components |

Materials: material only as per Appendix A |

|

Quality factor E: depending type of weld, radiography and material |

Quality factor E: depending type of weld, radiography and material |

Quality factor E: depending type of weld, radiography and material |

|

Factor y: factor depending Ferritic, Austenitic, Nickel and design temperature |

||

|

Factor W: weld strength reduction factor |

Factor W: weld strength reduction factor |

|

|

Factor f: stress range factor |

||

|

Factor F: design factor |

||

|

Factor T: temperature derating factor, compensate material allowable stress values for temperature, Table 841.166A |

||

|

Pipe under internal pressure (104.1.2 and 104.1.4 (in creep)):

P = internal design pressure D0 = outside diameter of pipe SE = maximum allowable stress, including quality factor tm = minimum required thickness y = coefficient table 104.1.2A A = additional thickness to compensate threading, provide additional strength, corrosion allowance W = Weld strength reduction factor when in creep range, is 1 outside creep range (table 102.4.7) |

Pipe under internal pressure (304.1.2):

P = internal design pressure D = outside diameter of pipe S = stress value for material E = quality factor t = pressure design thickness y = coefficient, also from table 304.1.1 W = Weld strength reduction factor |

Pipe under internal pressure (841.11):

P = internal design pressure D = nominal outside diameter of pipe S = specified minimum yield strength E = longitudinal joint factor, table 841.115A t = wall thickness F = design factor from table 841.114A T = Temperature derating factor from table 841.116A |

|

Bend under internal pressure (102.4.5):

pipe under internal pressure where I for intrados is:

and I for the extrados is:

and at sidewall I = 1.0, R = radius of pipe bend

|

Bend under internal pressure (304.2.1):

pipe under internal pressure where I for intrados is:

and I for the extrados is:

and at sidewall I = 1.0, R = radius of pipe bend

|

Bend under internal pressure (841.231): For cold bends the deflection of longitudinal axis and the radius is limited according table in paragraph 841.231

Hot bends are to be designed and manufactured according ASME B16.49, the internal pressure rating shall not be less than that which is calculated for straight seamless pipe and the intrados wall thickness should be:

where the t the wall thickness of the pipe is

|

|

Elbows under internal pressure (102.4.5): Elbows manufactured according standards listed in Table 126.1 are suitable for use at the pressure-temperature ratings specified by such standards.

Elbows not according above standards or for which design formulas and not given in the code shall be based on calculations consistent with the design criteria of this code. These calculations shall be substantiated by one or more of the means stated in A B C or D of 104.7.2 (Does this mean or allow that an elbow can be calculated according a bend with uniform thickness? Refer B31.3) |

Elbows under internal pressure (304.2.1): Elbows manufactured according standards listed in Table 326.1 are suitable for use at the pressure-temperature ratings specified by such standards.

Elbows not according above standards or for which design formulas and not given in the code shall be based on calculations consistent with the design criteria of this code. These calculations shall be substantiated by one or more of the means stated in A B C or D of 304.7.2, or the elbow can be calculated according the Bend calculation, refer 304.2.2. |

Elbows under internal pressure (841.231?): No specific design rules are listed for fabricated elbows

(Does this mean or allow that an elbow can be calculated according a bend with uniform thickness? Refer B31.3) |

|

Miter bends under internal pressure (104.3.3): 1. Only straight pipe calculations required if:

2. Pressure shall be limited to 70 kPa if:

and thickness is not less than required for straight pipe 3. Pressure shall be limited to 700 kPa if:

and thickness is not less than required for straight pipe 4. For pressure over 700 kPa: proof test, FEA, etc required with a defined minimum for closely spaced and widely spaced miter bend

|

Miter bends under internal pressure (304.2.3): 1. When theta =< 22.5 deg than max. allowable pressure shall be the lesser of (t = T - c):

and

2. When theta > 22.5 deg than max. allowable pressure shall calculated as (t = T - c):

For all miter bends the R1 shall not be less than:

with A: (T-c) =< 13 mm → A = 25 13 < (T-c) =< 22 mm → A = 2(T-c) (T-c) > 22 mm → A = 2(T-c)/3 + 30 |

Miter bends under internal pressure (841.232): 1. If system hoop stress > 40% of specified minimum yield strength miter bends are not permitted. Deflections caused by misalignment up to 3 deg are not considered as miters. 2. If 10% < hoop stress < 40% SMYS the deflection of each miter shall not exceed 12.5 deg. 3. If hoop stress < 10% SMYS the total deflection angle shall not exceed 90 deg. 4. If hoop stress > 10% SMYS the distance measured at the crotch shall not be less than one pipe diameter

|

|

Reducer under internal pressure (104.6): 1. Flanged reducer according Table 126.1 are considered suitable at the specified pressure temperature ratings. 2. Where butt welding reducers are made to a nominal pipe thickness, the reducers shall be considered suitable for use with pipe of the same nominal thickness. 3. Components not covered by the standards listed in Table 126.1 shall be based on calculation consistent with this code. Calculations are to be substantiated by one of: - extensive, successful service experience - experimental analysis - proof test - detailed stress analysis, such as finite element analysis (Is ASME VIII div.1 UG32 acceptable?) |

Reducer under internal pressure (304.6.1(b)): 1. Reducers according Table 326.1 shall be considered suitable for use at established pressure-temperature ratings or corresponding straight pipe with 87.5% of nominal wall thickness. 2. Concentric reducers not listed in Table 326.1 may be designed according closures as per ASME VIII div.1 3. Eccentric reducers not listed in Table 326.1 are qualified as unlisted components and shall be designed and documented substantiated by one of: - extensive, successful service experience - experimental analysis - proof test - detailed stress analysis, such as finite element analysis (Is ASME VIII div.1 UG32 acceptable?) |

Reducer under internal pressure (831.373): 1. Steel butt welded fittings shall comply with ASME B16.9 or MSS Standard Practice and shall have pressure and temperature ratings based on stresses for pipe of the same of equivalent material (831.31b) 2. Other pressure containing components shall be designed the according design philosophy of this code substantiated by one of: - extensive, successful service experience - experimental analysis - proof test - engineering calculations 3. Closure heads such as flat, ellipsoidal, spherical or conical heads are allowed for use under this code. Such items may be designed in accordance with ASME VIII div.1 (UG32). |

|

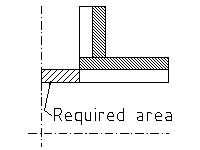

Stubon under internal pressure (104.3.1(D)): Required reinforcement area is

with

tr is reinforcement pad thickness

Assessment: Area A2,A3, A4 and A5 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 104.3.1(D.2.3))

|

Stubon under internal pressure (304.3.3): Required reinforcement area is

Assessment: Area A2, A3 and A4 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 304.3.3(f3))

If |

Stubon under internal pressure (831.4 and app. F): Required reinforcement area is (Fig. F-5):

Assessment: Area A2 and A3 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 831.4(f))

|

|

Tee (extruded outlet) under internal pressure (104.3.1(G)): Required reinforcement area is

K = 1.0 when K = K = 0.7 when

Assessment: |

Tee (extruded outlet) under internal pressure (304.3.4): Required reinforcement area is

K = 1.0 when K = K = 0.7 when

Assessment: If If |

Tee (extruded outlet) under internal pressure (831.4 ref. App. F): Required reinforcement area is

K = 1.0 when d/D > 0.60 K = 0.6+(2d)/(3D) when 0.15 < d/D <= 0.60 K = 0.7 when d/D <= 0.15

Assessment:

|

|

Weldolet (branch) under internal pressure (104.3.1(D)): Required reinforcement area is

with

Assessment: Area A2,A3, A4 and A5 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 104.3.1(D.2.3)) |

Weldolet (branch) under internal pressure (304.3.3): Required reinforcement area is

with

Assessment: Area A2, A3 and A4 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 304.3.3(f3)) |

Weldolet (branch) under internal pressure (831.4 ref. App. F): Required reinforcement area is (Fig. F-5):

Assessment: Area A2 and A3 to be multiplied by the ratio of allowable working stress, maximum multiplication factor is 1.0 (para. 831.4(f)) |

|

Cap under internal pressure (104.4.1(B)):

Can be calculated with ASME VIII div.1 UG-32 app.1-4

L = radius dish r = radius knuckle

|

Cap under internal pressure (304.4.1(b)): Can be calculated with ASME VIII div.1 UG-32 app.1-4

L = radius dish r = radius knuckle

|

Cap under internal pressure (831.372 and 831.373): Can be calculated with ASME VIII div.1 UG-32 app.1-4

L = radius dish r = radius knuckle

|

|

Flat closure under internal pressure (104.4.1(b)): Can be calculated with ASME VIII div.1 UG 34 …

|

Flat closure under internal pressure (304.4.1(b)): Can be calculated with ASME VIII div.1 UG 34 …

|

Flat closure under internal pressure (831.373): Can be calculated with ASME VIII div.1 UG 34 … |

|

Flange under internal pressure (104.5.1(B)): Can be calculated according ASME VIII div.1 app. 2 using B31.3 allowable stresses and temperature limits with:

|

Flange under internal pressure (304.5.1(b)): Can be calculated according ASME VIII div.1 app. 2 using B31.3 allowable stresses and temperature limits with:

|

Flange under internal pressure (831.2): Allowed to use: ASME B16 series as listed in Appendix A such as B16.5. Also MSS SP-44. For slip-on welding flanges reference is made to ASME VIII div.1 design.

Can ASME VIII div.1 be used for calculation? |

|

Blind flange under internal pressure (104.5.2(B)): Can be calculated according ASME VIII div.1 UG-34 with:

|

Blind flange under internal pressure (304.5.2(b)): Can be calculated according ASME VIII div.1 UG-34 with:

|

Blind flange under internal pressure:

Can ASME VIII div.1 be used? |

|

Blanks (spade) under internal pressure (304.5.3(B)):

|

Blanks (spade) under internal pressure (304.5.3(b)):

|

Blanks (spade) under internal pressure:

Can ASME VIII div.1 be used? |