When a component contains welds, the strength of the component can be influenced by creep in the welds at high temperatures. Creep will reduce the strength of the weld compared to the strength at low temperatures. The reduction in strength is incorporated in the calculations by a so-called weld strength reduction factor. Only the calculation codes ASME B31.1 and B31.3 have such a weld strength reduction factor. This factor is a different factor than the so-called joint efficiency factor, or joint quality factor or joint coefficient. For further information on this, see Joint quality factor.

The weld strength reduction factor in ASME B31.1 and ASME B31.3 has a value between 0.0 and 1.0 that is determined by the material and the design temperature. The weld strength reduction factor will be equal to 1.0 at low temperatures and will decrease at high temperatures. For the design temperature the weld strength reduction factor will be determined by interpolation.

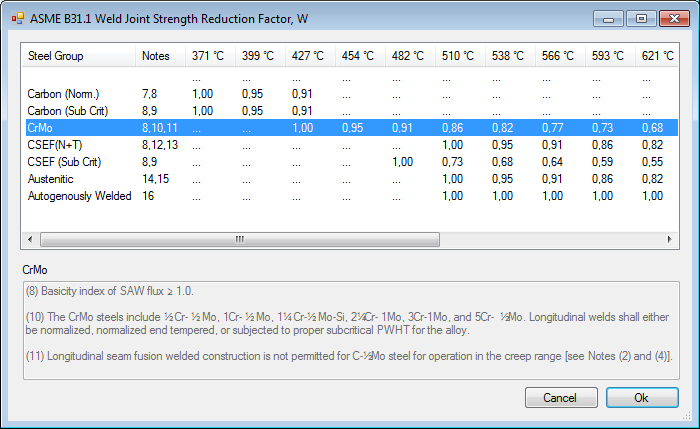

Weld strength reduction factor ASME B31.1

The selection of the weld strength reduction factor is via the material and the temperature. The material is organised in so-called steel groups that have a similar temperature behaviour. Every steel group has possibly some notes that prescribe the welding of the material. When selecting a steel group the notes will be displayed.

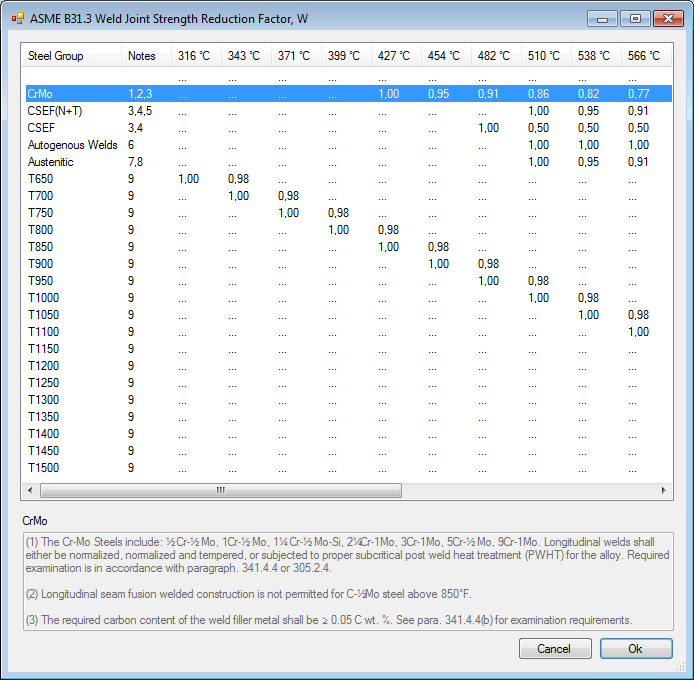

Weld strength reduction factor ASME B31.3

The selection of the weld strength reduction factor is via the material and the temperature. The material is organised in so-called steel groups that have a similar temperature behaviour. Every steel group has possibly some notes that prescribe the welding of the material. When selecting a steel group the notes will be displayed.