Input variables

Generic variables

These variables can be found in virtually all reports as input variables

- Design Pressure – Pd

- Pressure assumed to be present in the component according to the design terms

- Design Temperature – Td

- Temperature assumed to be present in the component according to the design terms

- Material cylindrical end

- Name of selected material used for the construction of the component

Specific variables

These variables are component specific

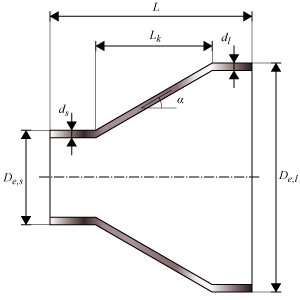

- Large/Small

- Large and Small refer to the large pipe end and the smaller (reduced) pipe end respectively

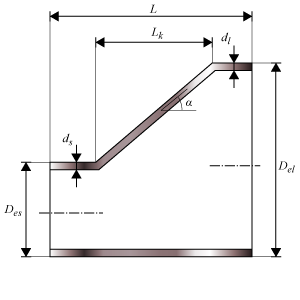

- Outside Diameter cylindrical end – De (Large/Small)

- Outside diameter of the attached part. The diameter runs from the outside of the wall to the opposite outside of the wall, through the center of the circle.

- Nominal Thickness cylindrical end – dn (Large/Small)

- Thickness ‘as is’, meaning it is the design thickness taking into account corrosion and tolerance.

- Corrosion – Ca

- Amount of thickness that accounts for the possible effects of corrosions.

- Tolerance – tol (Large/Small)

- Tolerance in thickness for production

- Strength reduction coefficient – z

- Effectiveness of the strength, depending on whether joints are seamless, welded, or expected to perform worse than the base material properties

- Overall length – L

- Length of the entire reducer

- Length conical part – Lk

- Length of the part that reduces gradually in diameter and hence, forms a conical shape

- Angle cone – α

- The angle of the conical section, or the slope with which the diameter reduces.

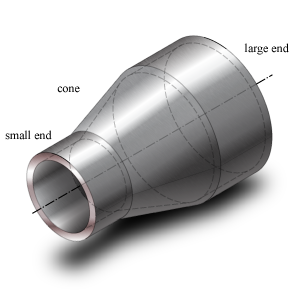

Concentric reducer

Concentric reducer dimensions

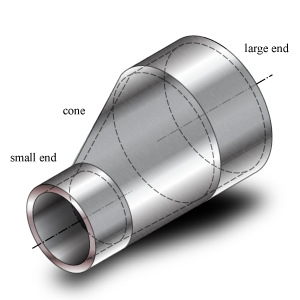

Eccentric reducer

Eccentric reducer dimensions

Calculated Values

- Allowable Stress cylindrical end at Temperature – f

- Stress in the component at which it is still allowed (without failure) to use the component

- Allowable stress cylindrical end at 20 °C – ft

- Stress in the component at which it is still allowed (without failure) to use the component at 20 °C ambient temperature

- Nominal Required Thickness cylindrical end – drn (Large/Small)

- Based on the input, this is the calculated thickness that is required to sustain the loads. The nominal value should be smaller than the nominal design thickness.

- Maximum Allowable Working Pressure – MAWP

- The maximum pressure at which the component can be used in operation. This value should be larger than the design pressure.

- Design margin – Pd / MAWP

- Ratio of the design pressure to MAWP

- Maximum Allowable Test Pressure – MATP

- The maximum pressure at which the component should be tested and survive.

Scope errors

- Design temperature material is out of scope.

- The material properties are not available at the design temperature.

- Cone angle is out of scope: required α ≤ 70° (paragraph 1).

- This code determines a maximum cone angle.

Errors

- Can’t find material ‘MaterialName’ in database

- Material could not be found in database. Select an existing material name, or select another material via the material selection window.

- Insufficient thickness cone at large end.

- Wall thickness is insufficient to bear the applied loads. Increase the wall thickness.

- Insufficient thickness cone at small end.

- Wall thickness is insufficient to bear the applied loads. Increase the wall thickness.