Input variables

Generic variables

These variables can be found in mostly all reports as input variables

- Gas infrastructure

- Location of the facility near which the gas infrastructure is situated.

- Underground, except a station

- In a tunnel

- Station

- Maximum Design Factor – fo

- Factor for restricting the allowable stress. The value can be chosen smaller, but not larger.

- Design Pressure – DP

- Pressure assumed to be present in the component according to the design terms

- Design Temperature – θ

- Temperature assumed to be present in the component according to the design terms

- Material (header/branch)

- Name of selected material used for the construction of the component

Specific variables

These variables are component specific.

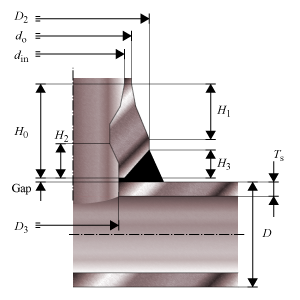

- Outside Diameter branch and header – do, D

- Outside diameter of the attached part. The diameter runs from the outside of the wall to the opposite outside of the wall, through the center of the circle.

- Inside Diameter – din

- Inside diameter at the top.

- Shoulder Diameter – D2

- Largest outside diameter.

- Diameter hole in header – D3

- Internal diameter opening between header and branch. Equal to the inside diameter at the bottom.

- Overall height branch – H0

- Height from top to bottom.

- Height at shoulder to branch – H1

- Height from the top to the largest outside diameter

- Height at inside beveled area – H2

- Height from the bottom to the smallest inside diameter.

- Height at welding area header – H3

- Available height at bottom for welding

- Gap between header and weldolet – Gap

- Clearance distance at bottom for welding

- Nominal Thickness Header – Tsn

- Thickness ‘as is’, meaning it is the design thickness taking into account corrosion and tolerance.

- Corrosion – Ca, Cah

- Amount of thickness that accounts for the possible effects of corrosion.

- Tolerance header – tolh

- Tolerance in thickness for production

- Strength reduction coefficient header – zh

- Effectiveness of the strength, depending on whether joints are seamless, welded, or expected to perform worse than the base material properties.

Weldolet dimensions

Calculated Values

- Allowable Operating Stress – S, Ss

- Stress in the component at which it is still allowed (without failure) to use the component. The additional h indicates the same variable but for the header.

- Allowable stress at 20 °C – St, Sst

- Stress in the component at which it is still allowed (without failure) to use the component at 20 °C ambient temperature. The additional suffix s indicates the same variable but for the header.

- Stress ratio – S/Ss, St/Sst

- Ratio of the allowable stresses in the branch and the header

- Reinforcement limit header direction – L

- Length from the branch outside diameter to the end of the header reinforcement zone.

- Reinforcement limit branch direction – H

- Length from the header outside diameter to the end of the branch reinforcement zone.

- Material area header – A0

- Cross-sectional area of header material between reinforcement limits.

- Material area branch – A1

- Cross-sectional area of branch material between reinforcement limits.

- Pressure area header – Ap0

- Cross-sectional area with pressure in header between reinforcement limits.

- Pressure area branch – Ap1

- Cross-sectional area with pressure in branch between reinforcement limits.

- Total pressure area – Ap

- Total cross-sectional area with pressure in header and branch between reinforcement limits.

- Pressure force – Fpa

- Total force of the design pressure on the total pressure area.

- Maximum allowable pressure force – Fpamax

- Maximum allwable force of the design pressure on the total pressure area.

- Minimum strength reduction coefficient at opening – zmin

- Minimum required effectiveness of the strength in the opening.

- Strength reduction coefficient at opening – z

- Effectiveness of the strength in the opening.

- Maximum Allowable Working Pressure – MAWP

- The maximum pressure at which the component can be used in operation. This value should be larger than the design pressure.

- Design margin – DP/MAWP

- Ratio of the design pressure to MAWP

- Maximum Allowable Test Pressure – MATP

- The maximum pressure at which the component should be tested and survive.

Scope errors

- Design pressure is out of scope: minimum operating pressure > 16 bar.

- This code determines a minimum pressure.

- Design temperature is out of scope: required -40 °C ≤ T ≤ 120 °C.

- This code determines a minimum and maximum temperature.

- Design factor is too large: required is fo ≤ fomax (see 7.2).

- This code determines a maximum design factor.

- No header pipe dimensions specified.

- A header pipe is needed for the calculations.

- Wall thickness header is out of scope according paragraph 7.9.2 Table 1.

- This code determines for headers a minimum thickness.

- Wall thickness branch is out of scope according paragraph 7.9.2 Table 1.

- This code determines for branches a minimum thickness.

Errors

- Can’t find material ‘MaterialName’ in database

- Material could not be found in database. Select an existing material name, or select another material via the material selection window.

- Insufficient wall thickness for header

- Wall thickness is insufficient to bear the applied loads. Increase the wall thickness of the header.

- Insufficient reinforcement area.

- Reinforcement area is too small. Increase the reinforcement area or thickness.

- Insufficient strength reduction coefficient for header: required is z ≥ zmin.

- Strength reduction coefficient is too small. Increase the reinforcement area or thickness.