Input variables

Generic variables

These variables can be found in mostly all reports as input variables

- Gas infrastructure

- Location of the facility near which the gas infrastructure is situated.

- Underground, except a station

- In a tunnel

- Station

- Maximum Design Factor – fo

- Factor for restricting the allowable stress. The value can be chosen smaller, but not larger.

- Design Pressure – Pc

- Pressure assumed to be present in the component according to the design terms

- Design Temperature – T

- Temperature assumed to be present in the component according to the design terms

- Material

- Name of selected material used for the construction of the component

Specific variables

These variables are component specific

- Outside Diameter – Do

- Outside diameter of the attached part. The diameter runs from the outside of the wall to the opposite outside of the wall, through the center of the circle.

- Nominal Thickness – en

- Thickness ‘as is’, meaning it is the design thickness taking into account corrosion and tolerance.

- Corrosion – c0

- Amount of thickness that accounts for the possible effects of corrosions.

- Tolerance – c1

- Tolerance in thickness for production

- Strength reduction coefficient – z

- Effectiveness of the strength, depending on whether joints are seamless, welded, or expected to perform worse than the base material properties

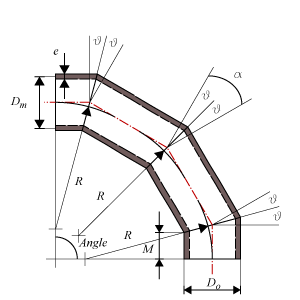

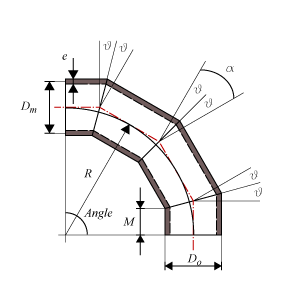

- Radius miter bend – R

- Radius of the miter bend from the origin of curvature and perpendicular to the neutral axis of the bend. The neutral axis follows the centerlines of the joints.

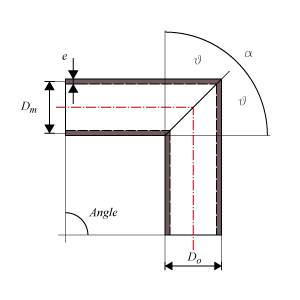

- Total deflection angle miter bend – Angle

- The angle of the total deflection the miter bend makes, i.e. the angle between the centerlines of the attached pipes.

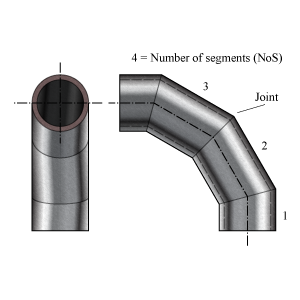

- Number of segments – NoS

- The number of joints in which the bend is divided.

Miter Bend

Multiple Miter Bend Widely Spaced

Multiple Miter Bend Closely Spaced

Single Miter Bend

Calculated Values

- Yield strength at operating temperature – Rt

- Stress in the component at which the component starts to plastically deform at operating temperature.

- Minimum yield strength at 20 °C – Rta

- Stress in the component at which the component starts to plastically deform at 20 °C ambient temperature

- Allowable Operating Stress – S

- Stress in the component at which it is still allowed (without failure) to use the component

- Allowable stress at 20 °C – St

- Stress in the component at which it is still allowed (without failure) to use the component at 20 °C ambient temperature

- Miter bend cut angle – θ

- Cutting angle between the different joints.

- Change of direction at miter joint – α = 2θ

- The total angle of deflection per miter joint.

- Maximum calculation pressure – Pc max

- Maximum pressure allowed when the stress is time dependent or not.

- Minimum miter bend radius – Rmin

- Minimum required bend radius

- Minimum inside length of sleeve segment ends – M

- Minimum length of the segment measured at the inside.

- Multiple/Single miter bend type

- A miter bend is called a multiple miter bend with 3 or more segments, otherwise a single miter bend with 2 segments.

- Nominal Required Thickness – ern

- Based on the input, this is the calculated thickness that is required to sustain the loads. The nominal value should be smaller than the nominal design thickness.

- Maximum Allowable Working Pressure – MAWP

- The maximum pressure at which the component can be used in operation. This value should be larger than the design pressure.

- Design margin – Pc/MAWP

- Ratio of the design pressure to MAWP

- Maximum Allowable Test Pressure – MATP

- The maximum pressure at which the component should be tested and survive.

Scope errors

- Design pressure is out of scope: minimum operating pressure > 16 bar.

- This code determines a minimum pressure.

- Design temperature is out of scope: required -40 °C ≤ T ≤ 120 °C.

- This code determines a minimum and maximum temperature.

- Design factor is too large: required is fo ≤ fomax (see 7.2).

- This code determines a maximum design factor.

- Wall thickness is out of scope according paragraph 7.9.2 Table 1.

- This code determines for miter bends a minimum thickness.

- Number of segments is out of scope: required is NoS ≥ 2

- A miterbend has at least 2 segments.

- For time dependent design stress: required Pc ≤ 0.4 MPa

- This code determines for loads that vary in time a maximum pressure.

- For time dependent design stress: required cycles ≤ 100

- This code determines for loads that vary in time a maximum number of cycles.

- For time independent design stress: required Pc ≤ 2 MPa

- This code determines for loads that are constant in time a maximum pressure.

- For time independent design stress and change in direction α > 22.5°: required cycles ≤ 7000

- This code determines for loads that are constant in time a maximum number of cycles.

- No calculation required when deflection angle per miter α ≤ 3°

- This code determines a minimum angle of miter cut θ. Decrease the number of miter segments or increase the total deflection angle of the miterbend.

- For multiple miter bends, the miter cut angle is out of scope: required is θ ≤ 22.5°

- This code determines for multiple miter bend a maximum angle.

- Miter bend radius is out of scope: required is R ≥ Rmin mm.

- This code determines a minimum radius.

Errors

- Can’t find material ‘MaterialName’ in database

- Material could not be found in database. Select an existing material name, or select another material via the material selection window.

- Insufficient wall thickness

- Wall thickness is insufficient to bear the applied loads. Increase the wall thickness.

Remarks

- For single miter bends, the miter cut angle θ is larger than 22.5°.

- The Maximum Allowable Pressure drops rapidly when the angle exceeds this limit.

Calculation errors

- Can't calculate required thickness. Please check input data.

- An error occured in the calculation for the required thickness.