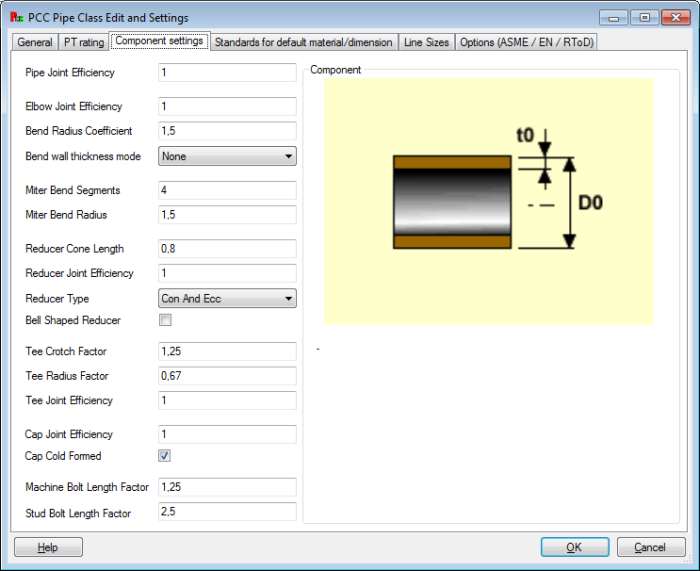

The pipe class edit window is activated by selecting in the main menu pipe class, 'New' or 'Edit'. The window consists of tabs which contain different pipe class settings. The tab component settings will be completed with data by the user as indicated below.

Pipe Class Edit Component Settings Pipe

The component settings are used in the calculations. The pipe joint efficiency factor for example has a direct effect on the overall strength of the pipe that can be used. The joint efficiency is related to the weld quality of the pipe or whether the pipe is seamless.

- 'Pipe joint efficiency', to set the pipe joint efficiency in the calculations. The value should be greater than 0 and smaller or equal to 1.

- 'Elbow joint efficiency', to set the elbow joint efficiency in the calculations. The value should be greater than 0 and smaller or equal to 1.

- 'Bend radius coefficient', to set the bend radius for custom bends.

- 'Bend wall thickness', to set possible undefined wall thickness at intrados and extrados. 'None' indicates that the wall thicknesses have to be given by the component or by the user, 'Voller Ausnutzungsgrad' will use the strongest version of the elbow/bend selected, 'Uniform' indicates that the bend/elbow will be of a uniform wall thickness.

- 'Miter Bend Segments', to set the default value for the number of segments of a miter bend.

- 'Miter Bend Radius', to set the default value for the miter bend radius.

- 'Reducer cone length', this is the length of the coned part in percentage of the overall length. The default value is 0.8 (or 80%).

- 'Reducer joint efficiency', to set the reducer joint efficiency in the calculations. The value should be greater than 0 and smaller or equal to 1.

- 'Reducer Type', to set whether to use concentric or eccentric or, concentric and eccentric reducers.

- 'Bell Shaped Reducer', to set whether to calculate the reducer as a conical shell with a bell shaped (knuckled) transition.

- 'Tee crotch thickness factor', to set the factor to calculate the wall thickness at the crotch. Refer to the formula in the window how the crotch thickness is calculated. The default value is 1.25

- 'Tee crotch outside radius factor', to set the outside radius of the tee in the crotch. The radius is not defined in the dimension standards and is usually defined by the customers who purchase the tees. The default value is 0.67

- 'Tee joint efficiency', to set the tee joint efficiency in the calculations. The value should be greater than 0 and smaller or equal to 1.

- 'Cap joint efficiency', to set the cap joint efficiency in the calculations. The value should be greater than 0 and smaller or equal to 1.

- 'Cap Cold Formed', to set whether the caps have been cold formed. This has an implication in certain calculation codes.

- 'Machine Bolt Factor', to set the length factor for machine bolts. This factor does not have any implication in the calculation and is only use to determine the length of the bolts in case of a fitting assembly, for example an orifice plate between gaskets and flanges.

- 'Stud Bolt Factor', to set the length factor for stud bolts. This factor does not have any implication in the calculation and is only use to determine the length of the bolts in case of a fitting assembly, for example an orifice plate between gaskets and flanges.

At the bottom of the dialog:

- 'Help' button, to show this help page

- 'OK' button, to save the edited data in the dialog to the database and close the dialog.

- 'Cancel' button, to cancel the edited data and close the dialog.