The strength of the component can be influenced by the welded seams or welded joints. The quality of the welds and the kind of weld can reduce the strength compared to the strength of the material of the component. The reduction in strength is incorporated in the calculations by a so-called joint quality factor or joint efficiency factor or weld joint factor or strength reduction coefficient depending on the calculation code. However, all calculation codes have such a factor or coefficient.

The joint quality factor has a value between 0.0 and 1.0 that is determined by the material, the kind of weld and the level of examination. When the examination is carried out more thoroughly, the joint quality factor may be increased in the calculation. With 2 or more welds in the component, the worst case condition regarding the welds must be evaluated to determine the value for the joint quality factor.

The PCC program provides if possible a selection of pre-defined values for the joint quality factor. The selected pre-defined factor will be used in the calculation. When the user wants to use a non-predefined value for the joint efficiency factor, the user must select a material that is manufactured without welded seams or welded joints.

Joint efficiency factor ASME B31.1

There is no selection necessary for the joint efficiency factor. The joint efficiency factor is already incorporated in the allowable stress. From the material database, used by the PCC program, the user can select the material (with the allowable stresses) via the material specification and manufacturing description.

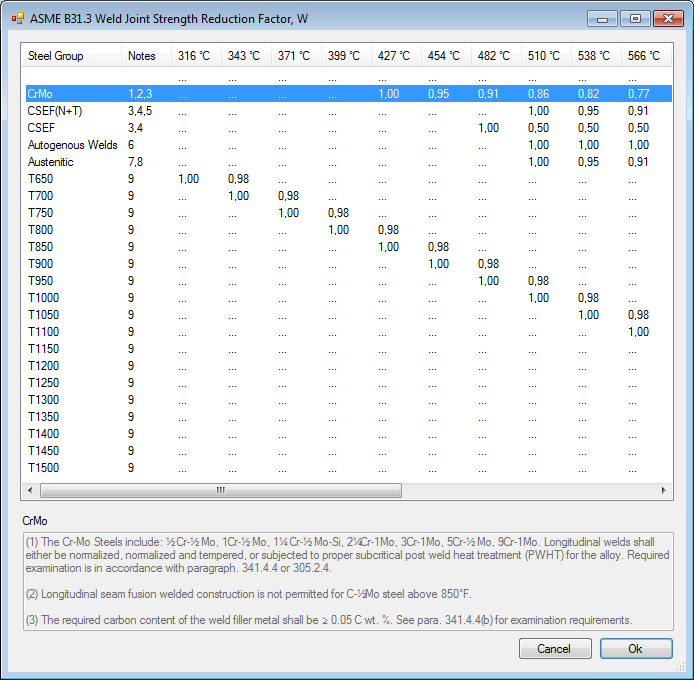

Joint quality factor ASME B31.3

The selection of the joint quality factor is via the material specification and manufacturing description. Every specification with description has possibly some notes that prescribe the welding of the material.

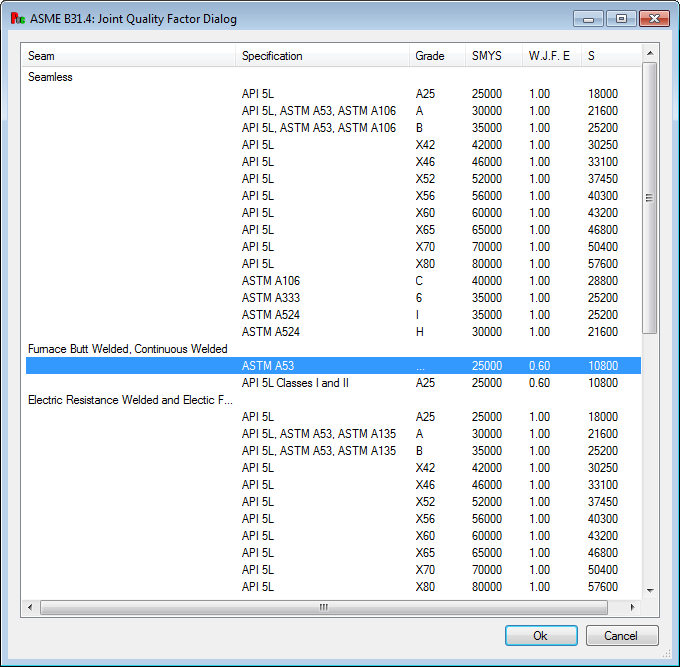

Weld joint factor ASME B31.4

The selection of the weld joint factor is via the manufactering description and the material specification. Every description with specification has possibly some notes that prescribe the welding of the material.

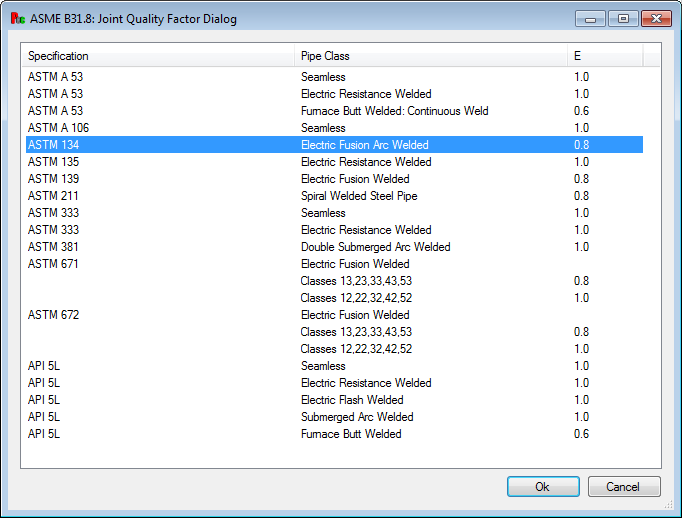

Joint factor ASME B31.8

The selection of the joint factor is via the material specification and the pipeclass (manufactering) description. Every specification with description has possibly some notes that prescribe the welding of the material.

Joint coefficient EN 13480

There is no selection available in the PCC program for the joint coefficient. The user must determine the value for the joint coefficient.

Joint coefficient EN 1594

There is no selection necessary for the joint coefficient. The joint coefficient is incorporated in the design factor. The design factor is determined by the location and the support of the component.

Strength reduction coefficient RToD

There is no selection available in the PCC program for the strength reduction coefficient. The user must determine the value for the joint coefficient.